Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China

If you have more questions to ask us and get best quote, please contact us now directly via

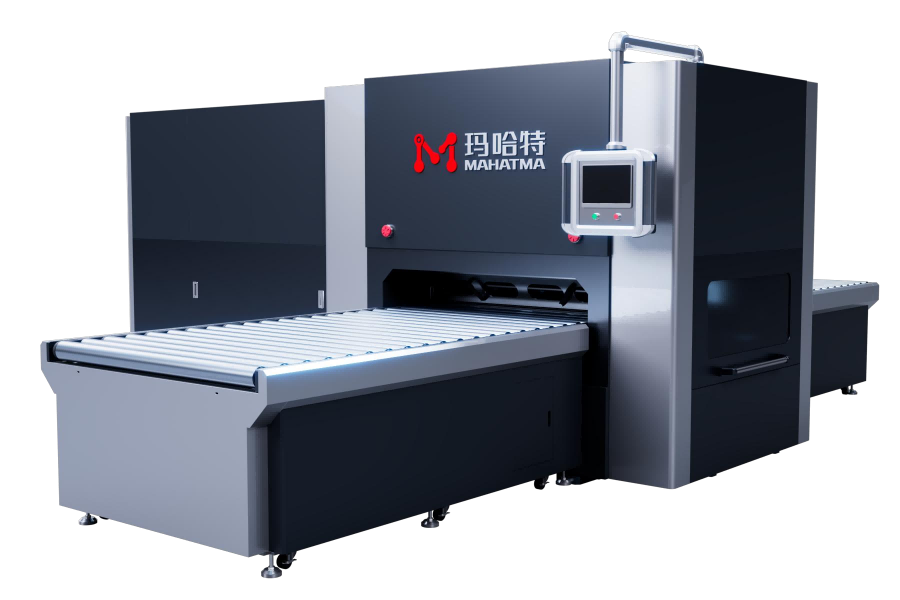

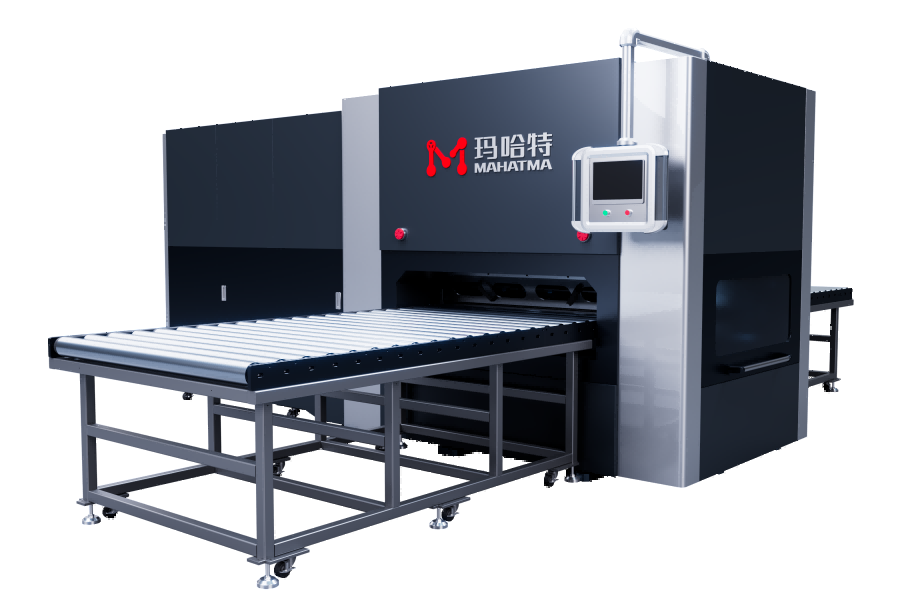

This serie of models adopts hydraulic and CNC technology imported from Germany, combining the accuracy of the servo control system and the powerful output of the hydraulic system. This makes it perform even better in processing large, thick and high-precision material leveling. Maintain a constant leveling reller gap to reduce deformation and ensure stable leveling effects. Parallel multi-rollers, hydraulic locking and dense support technology meet high-precision leveling needs. Compact design, small footprint, high processing accuracy and silent operation. Comparable with imported equipment, low cast and quick response, Quickly and accurately monitor component flatness with micron-level accuracy.

Suitable for fine surface requirements of large thick steel plates, non-ferrous metals, mirror sheets, sheet metal, laser cutting parts and flame cutting parts. The four- six-layer roller structure provides uniform roller force and high rigidity without leaving any rolling marks, hence can solve problems that are difficult to solve with general leveling, and has wider applicability. These advantages of hydraulic levelers make them an ideal choice for industries that require high-precision leveling, such as new energy, military industry, heavy machinery, automobiles and trucks, construction, ships, aviation, and metal processing.

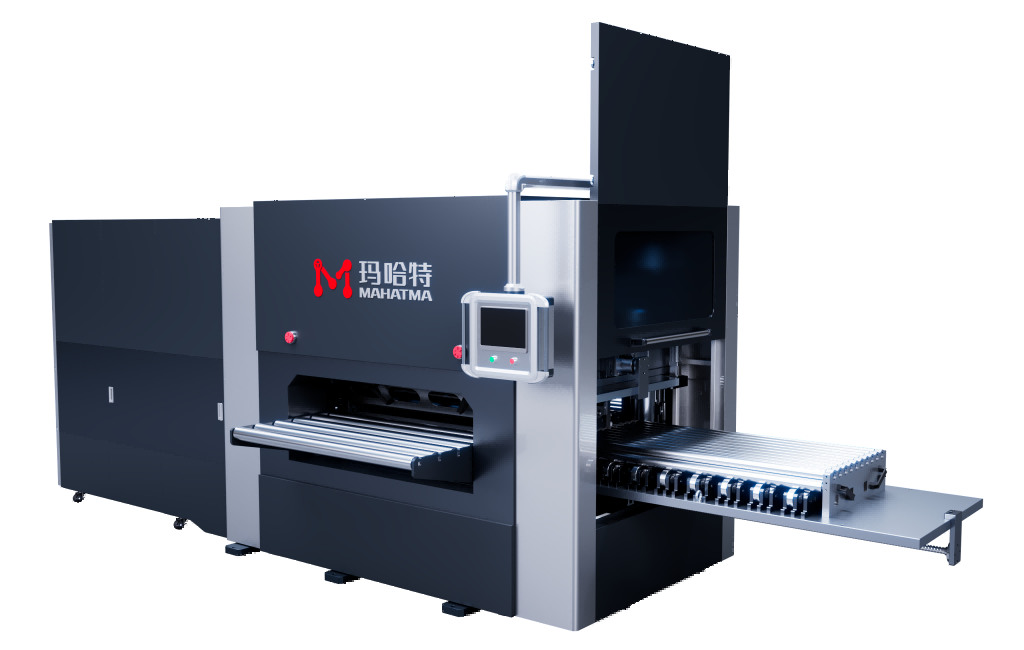

The Hydraulic Leveling Machine features an extra row of intermediate rolls between the upper and lower rows of leveling work rolls and support bearings, forming a multi-layered roller group structure with four or six layers. This design ensures uniform force distribution, excellent structural rigidity, minimal work roller bending deformation, high leveling accuracy, and effective harmonic attenuation.

The leveling rollers are optimally supported with minimal spacing between them. An integrated leveling gap adjustment device maintains a consistent gap throughout the leveling process, accommodating changes in the part's cross-sectional area. Even challenging parts, such as those from combustion cutting, can be leveled quickly and with minimal stress. This machine effectively addresses common issues like unevenness, roll imprinting, workpiece collapse, and sickle bending, enhancing sheet metal correction accuracy without leaving roll imprints on the material.

Key performance features include:

Powerful hydraulic pressure that maintains a consistent gap between leveling rollers, ensuring uniform correction for large quantities.

A 7-inch high-precision touch screen with PLC control for easy input, editing, and storage of process parameters.

Rapid flattening of stamped parts, plates, and components with minimal stress.

The precision leveling machine flattens metal plates through repeated bending with staggered rollers, adjusting the bending amount to prevent damage to the plate's appearance. This process aligns the metal fibers and eliminates internal stress, resulting in naturally flat plates. Precision leveling machines improve efficiency, reduce material waste, and lower labor costs compared to traditional leveling methods.

Inspired by the German ARKU Hydraulic Leveling Machine, this product features innovative design and advanced manufacturing, bridging the gap in domestic precision leveling equipment for plates and sheets. It matches the performance of German ARKU machines while controlling manufacturing costs to fit procurement budgets.

Peak Performance

The maximum leveling width is 6m, the maximum leveling thickness is 100mm, and the maximum accuracy can reach 0.01mm;

Mortise and Tenon Fuselage

Fully encircling the fuselage, it has super load-bearing capacity, saves space, and comprehensively improves stability and rigidity; it eliminates deformation and is stable and durable;

Subvert Tradition

Servo and hydraulic hybrid drive, precise force control and positioning, high torque and pressure, fine controllability, quick response;

Smart Benchmark

A new generation of intelligent super leveling control system; fully automatic and unmanned, real-time monitoring and adjustment, remote control, automatic counting etc;

Alloy Roller Set

Densely arranged full support structure enhances rigidity and improves precision. Alloy steel structure provides long-term and stable performance;

Strong Power

The hydraulic structure has strong and uniform leveling force, which can easily cope with the leveling needs of various high-quality metal materials;

Energy Saving and Environmental Protection

Compared with traditional hydraulics, it saves 70% energy consumption, is green and environmentally friendly, reduces meterial loss, improves production efficiency, and has lower maintenance costs;

Strong compatibility

It can adapt to various scenarios in the manufacturing industry and can handle various meterials from thin to thick, from soft to hard, with ultra-high applicability;

Anti-collapse function

Dynamic servo hydraulic compensation technology is used to prevent angle collapse and improve leveling accuracy and material surface quality

Model | MHTR 60-600 | MHTR 60-1000 | MHTR 60-1400 | MHTR 60-1650 | MHTR 60-2100 | MHTR 60-2600 | MHTR 60-3200 |

Width | 0-600mm | 0-1000mm | 0-1400mm | 0-1650mm | 0-2100mm | 0-2600mm | 0-3200mm |

Roll Diameter | φ60mm | φ60mm | φ60mm | φ60mm | φ60mm | φ60mm | φ60mm |

Roller Number | 21 | 21 | 21 | 21 | 21 | 21 | 21 |

Rated Plate Thickness | 1.0~8.0mm | 1.0~8.0mm | 1.0~8.0mm | 1.0~8.0mm | 1.0~8.0mm | 1.0~8.0mm | 1.0~8.0mm |

Max, Plate Thickness | 15.0mm | 15.0mm | 15.0mm | 15.0mm | 15.0mm | 15.0mm | 15.0mm |

Shortest part | 130mm | 130mm | 130mm | 130mm | 130mm | 130mm | 130mm |

Leveling Speed | 0-10m/min | 0-10m/min | 0-10m/min | 0-10m/min | 0-10m/min | 0-10m/min | 0-10m/min |

Voltage | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V |

Optional | 1.Loading and unloading and reclaiming manipulators2. Loading and unloading joint robots 3.Automatic detection platform 4. inlet and outflow assembly line 5. Automatic stacking lifting platform 6. Roller quick cleaning device | ||||||

CNC/electric adjustment are optional; other sizes, widths and speeds are customizable | |||||||

Applicable Object | Clat Parts, Sheet Metals,etc. | ||||||

Ttechnical Features | High Leveling Precision | ||||||

We provide not only equipment but also professional services throughout the entire lifecycle:

Simply fill out the form below as best you can. And don't sweat the details

Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China