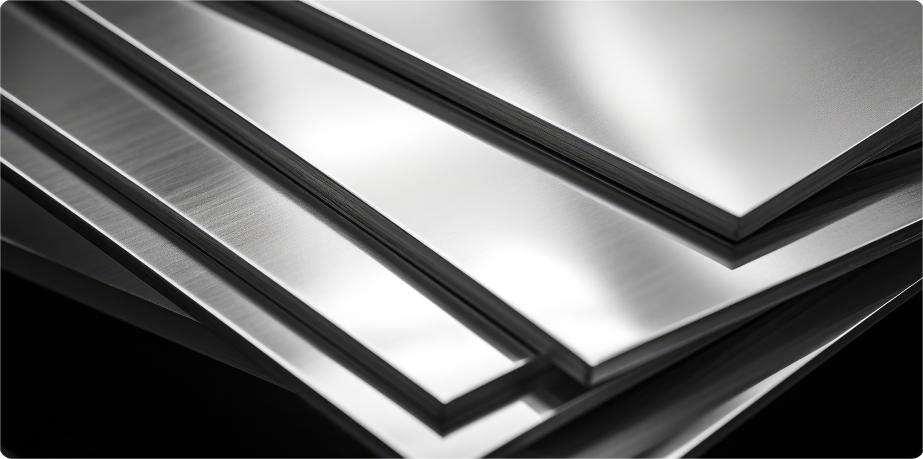

In modern industrial production, the flatness precision of metal sheets directly affects product performance and appearance. However, during the processing of metal sheets, bending and deformation issues often arise, impacting production efficiency and increasing the difficulty of subsequent processing. Mahatma leveling machines have successfully addressed this industry pain point through their innovative leveling technology.

High-Efficiency Leveling

Mahatma leveling machines utilize advanced servo drive systems and precision control systems to achieve rapid response and accurate leveling, significantly boosting production efficiency.

High-Quality Assurance

Through rigorous quality testing and practical application verification, Mahatma leveling machines ensure high flatness precision of the sheets, meeting high-precision processing demands.

Convenient Operation

Mahatma leveling machines feature user-friendly interfaces and intelligent control systems, simplifying the operation process so that even non-professionals can quickly master the equipment.

Easy to Learn and Use

Designed with the actual operational needs of users in mind, Mahatma leveling machines offer simplified steps and intuitive feedback, enabling operators to quickly acquire leveling techniques.

With their technological innovation, high efficiency, and ease of use, Mahatma leveling machines have brought significant changes to the metal processing industry. They not only resolve the issue of uneven sheets and workpieces but also enhance production efficiency and product quality, reducing business costs. Mahatma leveling machines are a valuable assistant for metal processing enterprises striving towards intelligent production.