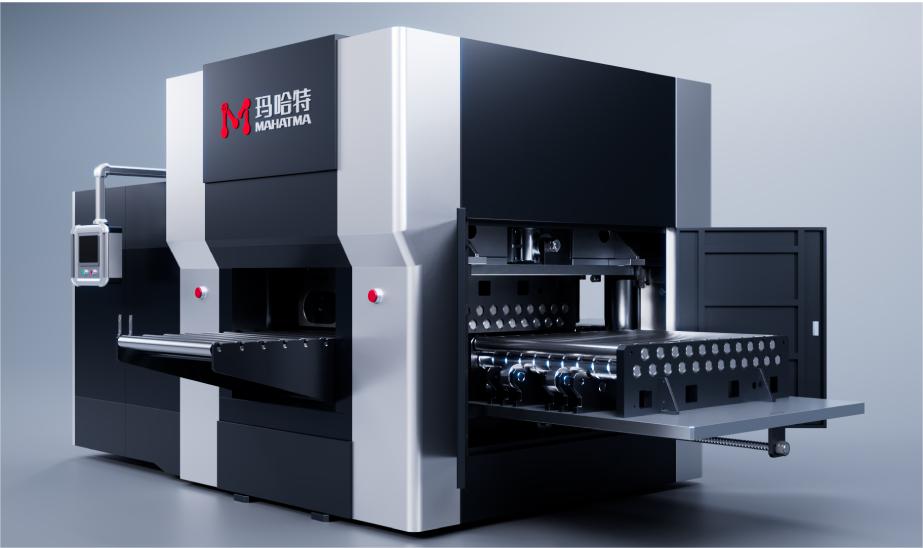

In the wave of industrial production, the concept of lean production has gradually become the core competitiveness of the manufacturing industry. The Mahatma leveling machine, with its outstanding performance and innovative technology, has become a powerful tool for replacing manual labor and achieving lean production. Lean production is a production management approach aimed at reducing resource consumption and creating greater value. Under this guiding principle, the Mahatma leveling machine emerged, effectively reducing waste in the production process and improving production efficiency through automated and intelligent operations.

High Efficiency: The Core Competitiveness of Mahatma leveling machine

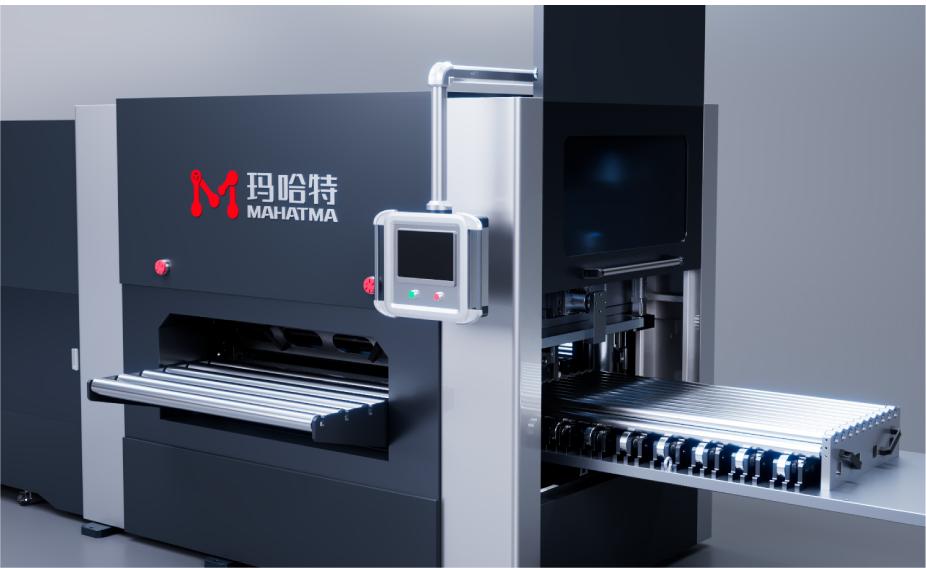

The Mahatma leveling machine adopts an advanced automated control system, enabling it to quickly respond to production demands and achieve high-speed, continuous leveling operations. Compared to traditional manual leveling, it significantly shortens the production cycle and enhances production efficiency.

High Quality: Ensuring Product Consistency

The Mahatma leveling machine, through its precise control system, ensures the consistency of each leveling operation's accuracy. This not only improves product quality but also reduces fluctuations in product quality caused by human factors.

What are its advantages?

Easy to Operate

Simplifies production processes—The Mahatma leveling machine has a user-friendly interface, making it easy to use even for operators without a professional background. The simplified operation process reduces the skill requirements for operators and minimizes the possibility of operational errors.

Easy to Learn and Use

Reduces training costs—The Mahatma leveling machine is designed with user-friendliness in mind. Its intuitive interface and simple operation process greatly reduce the training time and costs for new employees, allowing companies to quickly become productive.

High Cost-Performance Ratio

Balancing stable performance and economic benefits—The Mahatma leveling machine, with its long-term stable performance and economical maintenance costs, provides significant economic benefits for enterprises. The equipment reduces additional rework and waste caused by product quality issues, effectively lowering production costs, and bringing higher economic benefits to enterprises in long-term operations.