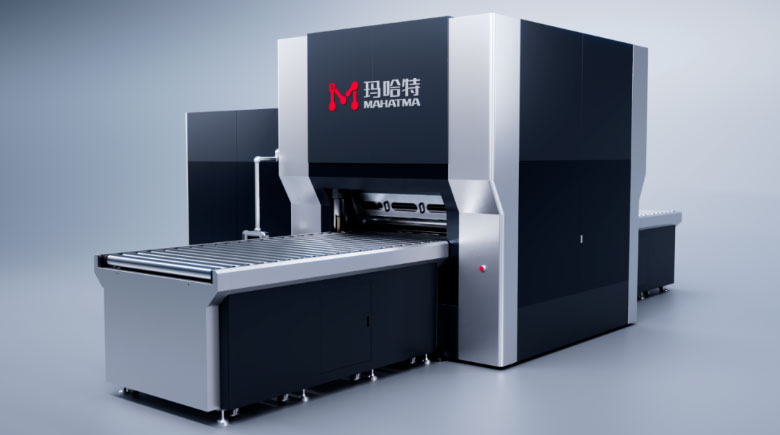

Precision leveling machines play a vital role in modern manufacturing, providing significant competitive advantages to businesses through increased efficiency, quality assurance, and streamlined operations. Here are the three major benefits of Precision Leveling Machines: Time-saving, Labor-saving, and Peace of mind!

Time-saving

1. Automated Operations: Precision leveling machines are equipped with automated control systems, reducing manual operation time.

2. Quick Adjustments: These machines can swiftly adjust leveling parameters to accommodate various thicknesses and materials of metal sheets, minimizing adjustment time.

3. Continuous Production: With high automation, precision leveling machines can achieve continuous production, minimizing production downtime.

Effort-saving

1. Reduced Manual Labor: Automated leveling processes reduce dependence on operators, lowering labor intensity.

2. Simplified Operation: User-friendly interfaces of precision leveling machines simplify the operation process, making it easy for operators to handle.

3. Decreased Material Handling: Efficient leveling machines reduce the frequency of manual material leveling, resulting in reduced material handling.

Worry-saving

1. Enhanced Quality: Precision leveling machines improve the flatness accuracy of metal sheets, reducing rework and scrap caused by material warping and deformation.

2. High Stability: These machines are designed and manufactured to prioritize stability and reliability.

3. Easy Maintenance: Precision leveling machines are easy to maintain, with straightforward maintenance tasks that reduce maintenance complexity and costs.

Precision leveling machines not only enhance production efficiency and product quality but also reduce production costs and maintenance complexities, leading to significant economic benefits for businesses. These advantages establish precision leveling machines as essential equipment in modern manufacturing.