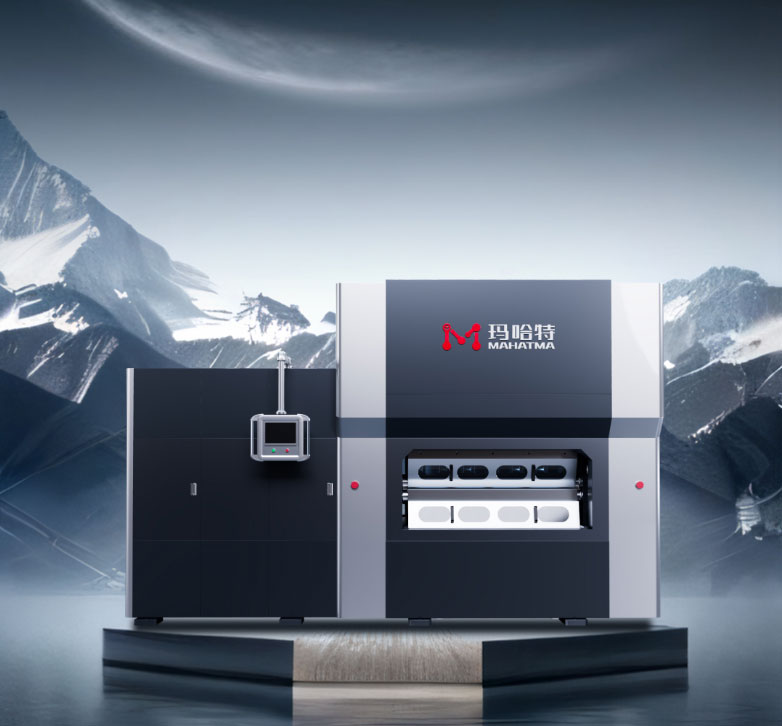

servo-hydraulic hybrid

A new generation of intelligent Super Platform control system

Tenon-and-mortise machine body, with super-strong bearing capacity

Servo and hydraulic hybrid drive: Combining the precise control of servo motors with the powerful thrust of hydraulic systems, it achieves efficient and high-precision operations.

Intelligent Super Platform control system: Equipped with a new generation of intelligent control systems, it monitors and adjusts the leveling process in real time, ensuring the accuracy and stability of each operation step.

Tenon-and-mortise structure machine body design: Using a traditional tenon-and-mortise structure improves the stability and torsional resistance of the whole machine, ensuring greater stability during operation.

Outstanding bearing capacity: The machine body is made of high-strength alloy steel material, manufactured with precise mechanical design and processing, capable of withstanding extremely high working pressures, meeting the demands of complex working conditions.

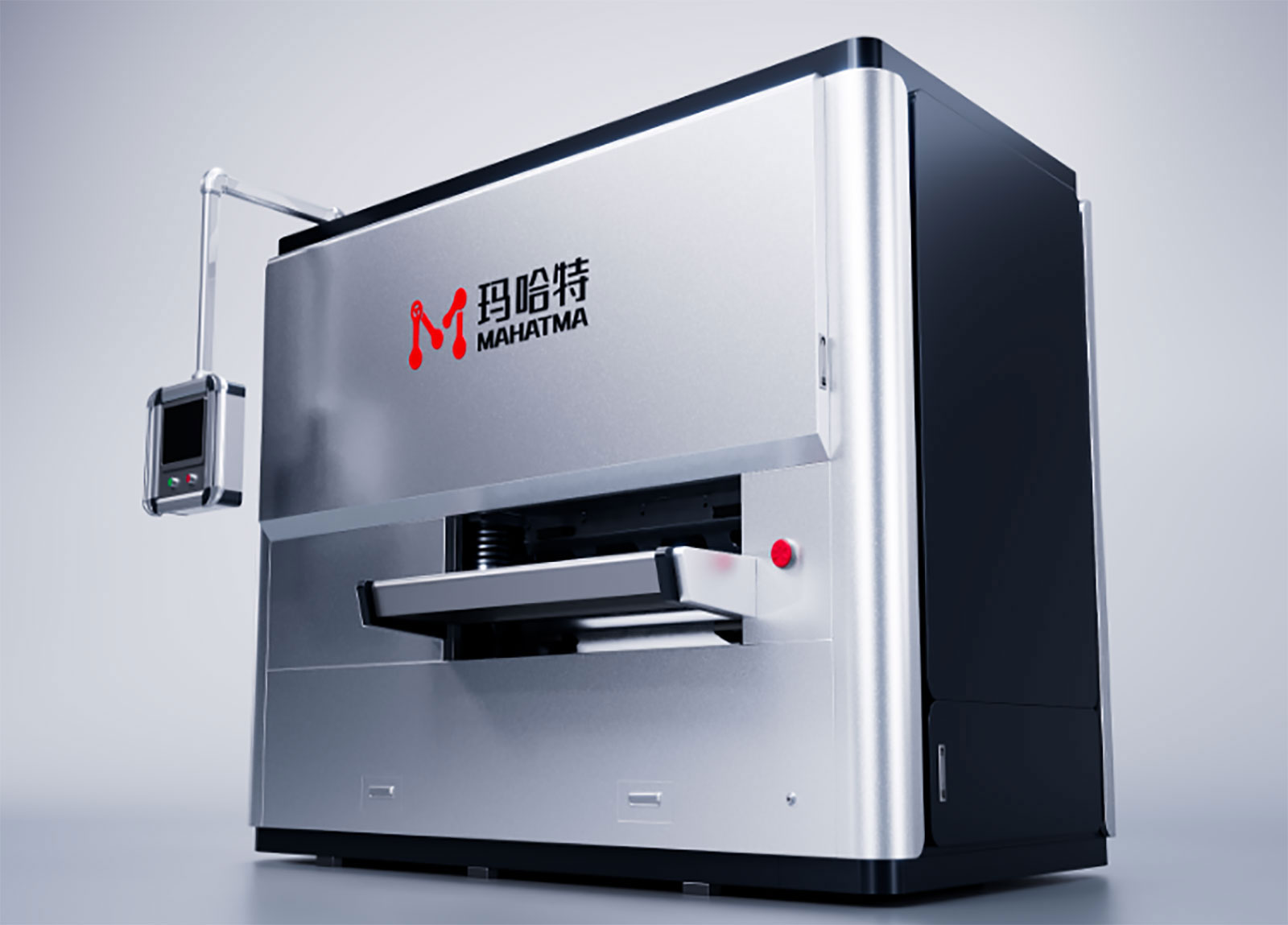

Cutting-edge performance

Smart Super Platform, achieving infinite possibilities

Maximum leveling width

Highest precision attainable

Energy-saving and eco-friendly

Strong power combined with environmental protection

Energy saving of 70%

Dual-motor powerful electric drive

Auxiliary function of Super Leveling

Intelligent Super Platform leveling technology

Remote control

Enables remote monitoring and control of equipment

Process parameter storage and editing

Allows free setting based on preset parameters such as plate thickness and width

Intelligent bidirectional reversal

Enables bidirectional entry or exit of materials, making it quick and convenient

Remote control: Supports remote monitoring and operation, allowing operators to understand equipment status in real time and make flexible adjustments from anywhere.

Process parameter storage and editing: Can store, call up, and edit various process parameters such as plate thickness and width, allowing for free setting according to specific requirements, improving production efficiency and flexibility.

Intelligent bidirectional reversal: The equipment supports intelligent bidirectional reversal, allowing for quick and convenient bidirectional material entry and exit, greatly improving production efficiency and operational convenience.

The leveling machine has a wide range of applications in industries such as metal processing, automobile manufacturing, and aerospace, providing excellent quality and precision for target products by improving the flatness and consistency of the sheet metal, helping companies achieve more efficient and reliable production.