Laser Cutting has become one of the most important manufacturing technologies in modern industry. From precision metal components to decorative wooden designs, laser cutters are widely used across multiple sectors. But what materials can be cut with a laser cutter, and how do different materials affect performance, quality, and cost?

What Is Laser Cutting?

Laser cutting is a thermal manufacturing process that uses a highly focused laser beam to cut, engrave, or mark materials. The laser melts, burns, or vaporizes material along a programmed path, producing clean edges and high dimensional accuracy.

Unlike traditional mechanical cutting, laser cutting is:

Non-contact

Highly precise

Repeatable

Suitable for complex shapes

This makes it ideal for both prototyping and mass production.

How Laser Cutting Works

A Laser Cutting System consists of:

A laser source (CO₂, fiber, or crystal laser)

Beam delivery optics

CNC-controlled motion system

Assist gas (oxygen, nitrogen, or air)

The laser beam is focused onto the material surface, where intense heat causes localized melting or vaporization. The assist gas removes molten material and improves cut quality.

This process is used in laser blanking, engraving, marking, and full-depth cutting.

Can Laser Cut Metal?

One of the most common questions in manufacturing is: can laser cut metal? The answer is yes—laser cutting is one of the most effective methods for cutting metal.

Laser cutting can process:

Thin to thick metal sheets

Tubes and profiles

Coiled metal stock

Fiber lasers are especially effective for metal cutting due to their high efficiency and power density.

Metals That Can Be Cut With a Laser Cutter

Carbon Steel

Carbon steel is one of the most commonly laser-cut materials. It offers:

Excellent edge quality

Fast cutting speeds

High accuracy

Widely used in Sheet Metal cutting service for industrial parts.

Stainless Steel

Stainless steel is ideal for laser cutting because it:

Produces clean edges

Requires no post-processing

Maintains corrosion resistance

Used extensively in food equipment, medical devices, and architectural components.

Aluminum

Aluminum can be laser cut, though it requires higher power due to reflectivity. Fiber lasers are preferred for aluminum processing.

Brass and Copper

Laser cutting of copper and brass is possible with advanced fiber lasers. These materials are often used in electrical and decorative applications.

Sheet Metal Cutting Service Applications

A professional sheet metal cutting service uses laser cutting to process:

Steel sheets

Aluminum plates

Stainless steel panels

Laser cutting ensures:

Tight tolerances

Smooth edges

Minimal material waste

This makes it ideal for enclosures, brackets, panels, and custom components.

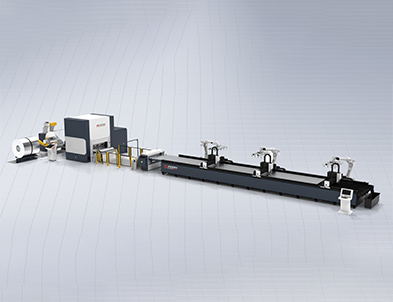

Tube Laser Cutting Services

Tube laser cutting services specialize in cutting round, square, and custom-shaped tubes. This technology allows:

Complex holes and slots

Angled cuts

Precise joints for welding

Tube laser cutting is widely used in:

Furniture manufacturing

Automotive frames

Fitness equipment

Structural components

Compared to traditional methods, tube laser cutting improves efficiency and design flexibility.

Laser Blanking and Coil Fed Laser Blanking

Laser blanking refers to cutting flat parts directly from metal sheets or coils using a laser instead of stamping dies.

Advantages of Laser Blanking

No tooling costs

Faster design changes

High flexibility

Coil fed laser blanking takes this process further by feeding metal coils directly into the laser cutting system. This enables:

Continuous production

Reduced scrap

Higher throughput

Coil fed laser blanking is widely used in automotive and high-volume manufacturing industries.

Non-Metal Materials That Can Be Laser Cut

Laser cutters are not limited to metal. Many non-metal materials can also be processed with excellent results.

Wood

Wood is one of the most popular laser cutting materials. Laser cutters can cut:

Plywood

MDF

Solid wood

Laser cutting creates smooth edges and allows intricate designs, making it ideal for crafts, furniture, and signage.

Acrylic (PMMA)

Acrylic is highly suitable for laser cutting:

Produces polished edges

No additional finishing required

Common uses include signage, display cases, and decorative panels.

Plastics

Some plastics can be laser cut, including:

ABS (limited)

PET

Polycarbonate (thin sheets)

Material selection is critical, as some plastics release harmful fumes.

Leather and Fabric

Laser cutters are widely used for cutting:

Leather

Cotton

Felt

Synthetic fabrics

This is common in fashion, upholstery, and custom accessories.

Paper and Cardboard

Laser cutting is ideal for:

Packaging prototypes

Invitations

Craft designs

It allows high-speed cutting with intricate detail.

Materials That Should NOT Be Laser Cut

Not all materials are suitable for laser cutting.

Avoid cutting:

PVC (releases toxic chlorine gas)

Vinyl

Fiberglass

Certain coated metals

Always verify material safety before laser cutting.

Laser Cutting vs Laser Engraving

Laser cutting removes material completely, while engraving marks the surface.

The best laser engraver often supports both cutting and engraving, allowing:

Logos

Text

Decorative patterns

This versatility is valuable for custom products and branding.

Choosing the Right Laser Cutting Service

When selecting a laser cutting service, consider:

Material capability

Maximum thickness

Tolerance requirements

Production volume

Professional services offer advanced equipment for tube laser cutting services, sheet metal cutting service, and coil fed laser blanking.

Benefits of Laser Cutting Technology

Laser cutting offers multiple advantages:

High precision

Clean edges

Minimal waste

Automation-ready

Suitable for prototyping and mass production

These benefits explain why laser cutting is widely adopted across industries.

Industrial Applications of Laser Cutting

Laser cutting is used in:

Automotive manufacturing

Aerospace components

Electronics enclosures

Medical devices

Architectural metalwork

The ability to answer can laser cut metal confidently has transformed modern manufacturing.

Future Trends in Laser Cutting

Advancements in laser technology include:

Higher-power fiber lasers

Improved automation

AI-assisted nesting

Faster coil fed laser blanking systems

These innovations will continue expanding the range of materials that can be processed.

Conclusion

So, what materials can be cut with a laser cutter? From metals like steel, aluminum, and stainless steel to non-metals such as wood, acrylic, leather, and fabric, laser cutting is an incredibly versatile manufacturing process.

Whether you need a sheet metal cutting service, advanced tube laser cutting services, or high-efficiency coil fed laser blanking, laser cutting delivers precision, flexibility, and efficiency. With the right equipment or professional laser cutting service, the possibilities are vast—and constantly expanding.