In the Metal Processing industry chain, steel plate leveling is a critical bridging process that connects preceding and subsequent stages. Mahatma provides a series of steel plate leveling solutions tailored to the diverse requirements of different industries for flatness, efficiency, and cost. These solutions cover a wide range of applications, from thin-sheet electronic enclosures to thick-plate construction machinery.

For thin plate applications (0.5–3.0mm) in industries such as telecommunications and home appliances, the equipment utilizes a four-roller structure combined with servo tension control. Leveling speeds can reach up to 15 m/min, with flatness controlled within ±0.05 mm/m. In a 5G base station cabinet project, leveled plates could proceed directly to the automated bending line without manual correction, increasing production line efficiency by approximately 40%.

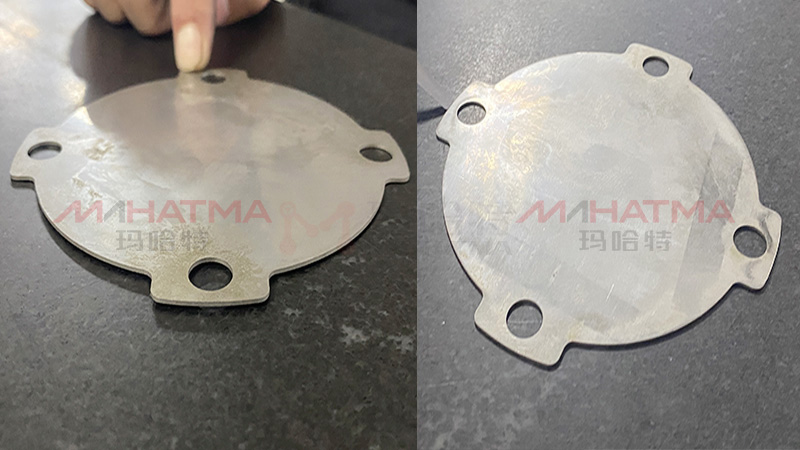

For medium-thick plate applications (3–12mm) in areas such as automotive structural components and energy storage cabinet bodies, Mahatma employs a six-roller + hydraulic locking system to ensure a significant reduction in residual stress in high-strength steel after leveling. Customer feedback indicates notable improvements in laser cutting dimensional stability and welding gap qualification rates.

For ultra-thick plate applications (12–60mm) in sectors such as wind power and shipbuilding, the equipment features a high-rigidity frame and dense support roller assemblies to effectively prevent center sagging. At a pressure vessel factory, 40mm Q345R steel plates achieved a straightness of ±0.2 mm/m after leveling, meeting the requirements for circumferential welding and alignment.

All models support modular configurations, including integration with automatic thickness measurement, fixed-length cutting, loading/unloading platforms, or MES communication interfaces, allowing flexible adaptation to the pace of enterprise automation upgrades. The operation interface offers multilingual support and process parameter storage functions, reducing reliance on skilled operators.

A procurement manager from Hebei stated, "We used to consider leveling merely an auxiliary process, but now we realize it directly impacts downstream product yield and delivery cycles." Another customer from Dongguan mentioned that after one year of equipment operation, the comprehensive material utilization rate increased by approximately 3 percentage points.

Mahatma's technical team notes that scientific steel plate leveling not only improves appearance but also enhances material processing stability through stress release. As manufacturing requirements for process control increase, pre-leveling is transitioning from an "optional" to an "essential" step.

Currently, Mahatma has established multiple technical service centers nationwide, offering process diagnostics, equipment selection, and operational training support to help enterprises properly configure their leveling capabilities. In the future, as concepts of flexible manufacturing and lean production deepen, intelligent and highly compatible leveling equipment will continue to play a foundational role.