Amidst the accelerated transition of the manufacturing industry toward flexibility and intelligence, the home appliance sector—a traditionally strong industry in China—is confronting multiple challenges such as a surge in small‑batch, high‑variety orders, compressed delivery cycles, and rising labor costs. Particularly in the processing of metal structural components, traditional segmented production models are struggling to meet market demands for high quality and rapid response.

Recently, a leading domestic home appliance manufacturer upgraded its Sheet Metal pre‑processing line by successfully integrating a Mahart laser uncoiling, leveling, and feeding production line. This upgrade has enabled fully unmanned operations from raw materials to semi‑finished products, providing the industry with a replicable model for intelligent transformation.

Traditional Model Becomes Unsustainable, Urgent Need for Process Innovation

The company produces over 30 million units of various home appliances annually, with key components such as casings, brackets, and inner liners heavily utilizing 0.5–2.0mm stainless steel and galvanized sheets. The previous decentralized process of "coil uncoiling/leveling + manual handling + single-machine laser cutting" presented three major pain points: First, micro-deformations in sheets after multiple transfers made it difficult to guarantee laser cutting precision. Second, ultra-thin stainless steel was prone to pressure marks during traditional roller-based conveyance, affecting the appearance quality of premium products. Third, manual parameter adjustments were required during order changeovers, with setup times as long as 40 minutes, severely constraining production line flexibility.

"Annually, our hidden costs in material waste, rework, and manual handling exceed 8 million RMB," the company's production manager admitted. "More critically, customer demands for product flatness and consistency are increasingly stringent, and the traditional model has reached its capability ceiling."

Customized Solution, Creating a Seamless End-to-End Process

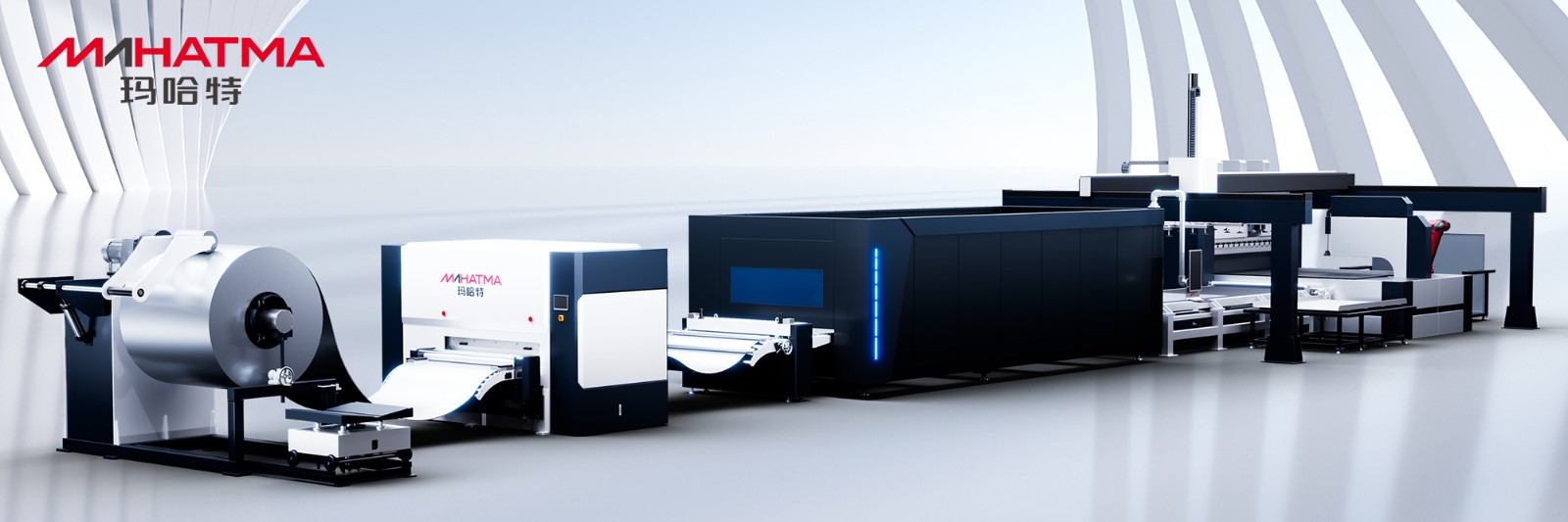

After multiple rounds of technical evaluation and on-site inspections, the company ultimately selected the customized Mahatma laser uncoiling, leveling, and feeding production line. The core of this solution lies in breaking down process barriers, deeply integrating four major modules—automatic loading, high-Precision Leveling, belt-supported conveyance, and dual-head laser cutting—and implementing several optimizations tailored to the home appliance industry's characteristics:

First, the adoption of Mahatma's self-developed ultra-precision leveling technology (±0.01mm), utilizing multi-roller zoned dynamic adjustment to completely eliminate thin sheet edge wave and internal stress. Second, the innovative use of a fully enclosed, belt-supported conveying structure that avoids surface pressure marks caused by traditional metal rollers, particularly suitable for stainless steel panels requiring high surface finish. Third, integration of an AI-based intelligent nesting system that automatically recognizes product drawings and optimizes layouts, significantly improving material utilization. Fourth, the entire line is integrated with an Industry 4.0 collaborative control system, supporting seamless connection with the company's MES for order-driven production.

During project implementation, Mahatma's technical team was stationed at the factory for two weeks. They repeatedly adjusted parameters for key materials like 0.6mm ultra-thin stainless steel and 1.2mm galvanized sheets, ultimately determining the optimal leveling curves and cutting paths. Concurrently, to minimize disruption from the production line upgrade, a phased transition strategy was adopted to ensure a smooth switch from the old to the new system.

Value Demonstrated: Triple Optimization of Quality, Efficiency, and Cost

Six months after commissioning, the performance data is remarkable:

Production Efficiency: Daily coil processing capacity per line increased from 8 tons to 13.5 tons; emergency order response time shortened by 65%.

Product Quality: Surface scratch rate on stainless steel panels decreased by 90%; laser cutting dimensional accuracy stabilized within ±0.05mm; customer complaint rate reduced by 42%.

Cost Structure: Material utilization rate improved from 88% to 96%, yielding annual raw material cost savings exceeding 3 million RMB. Manpower per line reduced from 5 workers to 1, saving over 700,000 RMB annually in labor costs.

The leap in flexible manufacturing capability is even more noteworthy. This laser uncoiling, leveling, and feeding line supports over 200 preset product parameter sets, reducing changeover time to under 8 minutes.

The value of this case lies not only in the advanced nature of the equipment itself but also in redefining the logic behind building a "smart factory." True intelligence is not simply about accumulating robots and sensors but involves reconstructing fundamental processes to solve long-standing quality and efficiency bottlenecks. The successful application of Mahatma's laser uncoiling, leveling, and feeding production line provides a replicable upgrade path for light manufacturing sectors like home appliances, kitchen appliances, and electronics.

As China's manufacturing sector climbs the value chain, the intelligence level of foundational process equipment will become a core competitive advantage. It is foreseeable that companies like Mahatma, deeply focused on niche technological fields, will continue to assist more manufacturing enterprises in solidifying their foundations for high-quality development and gaining initiative in global competition through integrated innovation of "process + intelligence." The value of laser uncoiling, leveling, and feeding production lines will also gradually evolve from being "a tool for cost reduction and efficiency improvement" to becoming "the core enabler of an enterprise's flexible manufacturing capability."