A rotary laser level is one of the most widely used precision measurement tools in construction, interior installation, surveying, and industrial manufacturing. Whether you are leveling floors, aligning walls, setting foundations, or calibrating machinery, understanding how a rotary laser level works will significantly improve work accuracy and efficiency. Compared with a digital level, the rotary type covers larger areas, provides 360-degree reference lines, and performs reliably in both indoor and outdoor environments.

1. What Is a Rotary Laser Level?

A rotary laser level is a self-leveling measuring tool that projects a 360-degree horizontal or vertical rotating laser beam across a jobsite. Unlike a standard laser level that emits a single straight line, a rotary model uses a fast-spinning head to generate an entire reference plane. This makes it ideal for:

Long-distance leveling

Large construction sites

Excavation and grading

Floor leveling

Machinery alignment

Industrial Automation setups

Rotary lasers can project at distances of up to 500–1500 meters, especially when paired with laser receivers.

2. How Does a Rotary Laser Level Work? (Core Principle)

Understanding the working principle helps users select the right device and maximize accuracy.

2.1 Internal Components

A typical rotary laser level includes:

Laser diode – emits a sharp, visible beam

Spinning head / Rotor – rotates the beam at high speed

Self-leveling pendulum or electronic leveling sensors

Motor system – maintains rotation speed

Microprocessor – controls leveling and calibration

Receiver / Detector (for long-range applications)

2.2 Working Mechanism

Here is the simplified sequence of how a rotary laser level works:

Laser emission

The diode emits a narrow beam.Beam rotation

The internal motor spins a mirror or head at speeds between 300–1200 RPM.

This creates a 360-degree plane of light.Self-leveling

The pendulum or electronic sensors automatically adjust the device to ensure the laser plane is perfectly level.

High-end models like the Topcon laser level use electronic servo motors and gyroscopic sensors for extra precision.Reference plane creation

The rotating beam forms a continuous horizontal or vertical reference plane visible to the naked eye or detected by a receiver.Measurement & alignment

Workers can use the laser plane to determine accurate heights, align structures, set slopes, or level surfaces.

This operating principle allows the rotary laser level to outperform handheld levels, line lasers, and even a digital level in large-area jobs.

3. Applications of a Rotary Laser Level

Rotary laser levels are extremely versatile in construction and industrial environments.

3.1 Construction & Building

Foundation leveling

Wall alignment

Ceiling installation

Pipeline elevation calibration

Floor leveler preparation

Tile installation

3.2 Landscape & Outdoor Work

Grading

Excavation leveling

Fence alignment

Drainage system installation

3.3 Industrial Applications

Rotary laser levels provide essential support for:

Flexible production line setup

Machine installation and alignment

Robot positioning

Conveyor system leveling

Warehouse racking installation

Their consistent accuracy ensures smooth operation and reduces production downtime.

4. Advantages of Using a Rotary Laser Level

Covers large areas (up to hundreds of meters)

A single rotating beam replaces multiple workers using manual tools.

High precision & automatic calibration

Self-leveling sensors ensure consistency.

Durable and suitable for indoor/outdoor use

Supports harsh environments, especially construction sites.

Time-saving

Tasks like leveling foundations, floors, or ceilings become significantly faster.

Compatible with receivers

Allows long-distance work even under bright sunlight.

Compared with a digital level, the rotary type is more suitable for large-scale surveying and alignment.

5. How to Use a Rotary Laser Level (Step-by-Step Guide)

Many users ask: how to use a rotary laser level correctly?

Below is a simple, professional method applicable to most job sites.

Step 1: Set Up the Tripod

Place a sturdy tripod on the ground.

Ensure it’s stable and positioned on relatively level terrain.

Step 2: Mount the Rotary Laser Level

Attach the device securely to the tripod base.

Switch the tool on.

Step 3: Enable Self-Leveling

Most modern rotary lasers self-level automatically.

Wait 5–15 seconds for stabilization.

Step 4: Turn On the Laser Rotation

Activate the rotating head.

The beam will now form a 360° plane.

Step 5: Use a Laser Receiver (Outdoor or Long Distance)

Attach the receiver to a measuring rod.

Move the rod until it detects the laser line.

Adjust height until the receiver beeps steadily.

Step 6: Mark or Adjust

Depending on your task:

Mark reference heights

Level a floor

Align walls or ceilings

Set slope grade (advanced models)

Step 7: Re-check Measurements

For accuracy, always verify multiple points on the jobsite.

6. Rotary Laser Level vs Digital Level: Which Is Better?

| Feature | Rotary Laser Level | Digital Level |

|---|---|---|

| Coverage area | Very large | Limited |

| Speed | Fast | Slow |

| Best use | Construction, grading, industrial | Interior leveling, small jobs |

| Accuracy | High | Very high |

| Cost | Higher | Lower |

In summary:

Choose digital level for small-scale interior tasks.

Choose rotary laser level for construction, large surfaces, and industrial alignment.

7. Why Many Professionals Prefer Topcon Laser Level

Topcon laser level models are known for:

High accuracy (±1.5 mm at 30 m)

Long-range capability

Strong durability

IP-rated waterproof and dustproof designs

Auto slope functions

They are a trusted choice in civil engineering, surveying, and industrial machinery alignment.

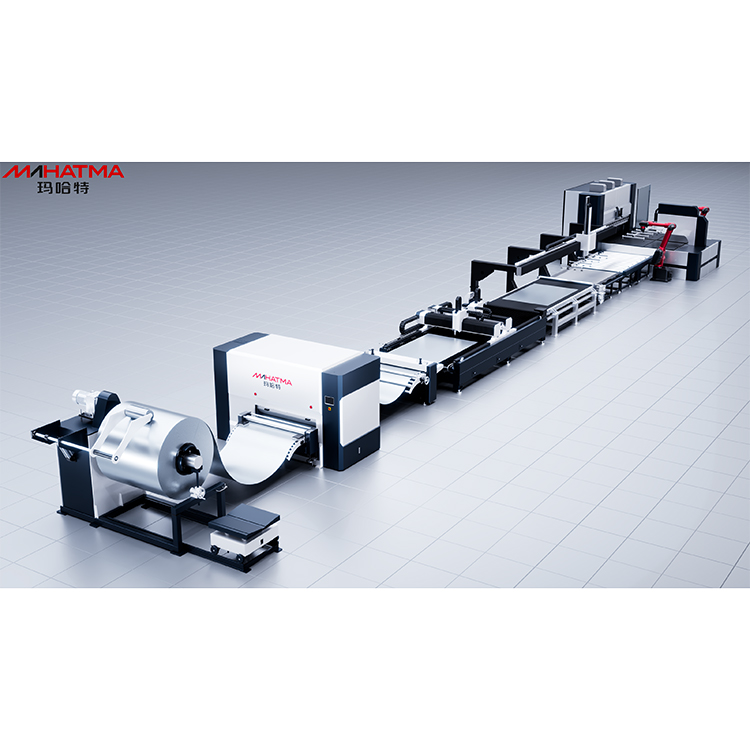

8. How Rotary Laser Levels Support a Flexible Production Line

Modern automated factories rely heavily on precise alignment.

Rotary lasers help with:

Conveyor line straightness

Equipment leveling

Robotic arm positioning

Quality control systems

Layout changes and modular line expansion

This ensures stable, efficient, and high-precision production operations.

Conclusion

A rotary laser level is an essential tool for anyone involved in construction, surveying, interior installation, or industrial engineering. By understanding how a rotary laser level works, the components involved, and learning how to use a rotary laser level correctly, users can achieve superior accuracy and efficiency in all leveling and alignment tasks.

Whether comparing it with a digital level, using it as a floor leveler, or integrating it into a flexible production line, the rotary laser level remains one of the most powerful precision tools available today. For professionals seeking premium quality and performance, brands such as Topcon laser level offer industry-leading reliability.