In modern manufacturing, the term product line is often used to describe a group of related products offered by a company. However, from an operational perspective, a product line is more than just a collection of items—it is supported by a sophisticated production line that ensures efficiency, precision, and quality consistency. One of the most innovative examples in today’s industrial landscape is the Belt-supported Non-Destructive Cutting Flexible Production Line, a solution that combines high-speed automation, precision engineering, and adaptability for modern manufacturing needs

1. Understanding a Product Line in Manufacturing

A product line refers to a set of related products that a company manufactures or markets under a specific category. These products share similar design elements, technologies, or target markets. For example, a machinery manufacturer may have a product line that includes various models of precision cutting equipment, each tailored for different industries or material types.

The operational backbone of any product line is the production line—a sequence of machines, equipment, and workflows that transform raw materials into finished products. Efficient production lines not only enhance productivity but also maintain product quality, reduce costs, and improve response times to market demand.

2. The Evolution of Production Lines

Traditional production lines were linear and rigid. They relied heavily on human labor and sequential processes. While effective for mass production, these lines lacked flexibility and required significant downtime for changeovers or product adjustments.

With advances in automation, robotics, and precision machinery, modern production lines have evolved into flexible production lines, capable of adapting to multiple products, varied sizes, and changing specifications with minimal downtime. This flexibility is critical in industries where product variations are frequent, or where high precision and non-destructive processing are essential.

3. Introduction to the Belt-Supported Non-Destructive Cutting Flexible Production Line

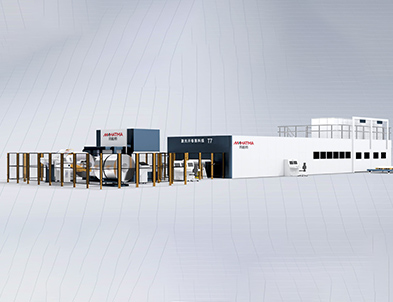

The Belt-supported Non-Destructive Cutting Flexible Production Line is a cutting-edge solution designed to combine high-speed manufacturing with material safety and precision. Unlike conventional cutting lines that may deform or damage materials, this line employs a belt-supported system to transport materials steadily while non-destructive cutting technologies ensure the integrity of each piece.

Key Features of This Production Line

Belt-Supported Transport

The use of belts provides smooth, continuous material movement. This reduces vibration and mechanical stress, ensuring precision in cutting operations.Non-Destructive Cutting

Materials are processed without causing structural damage, preserving the integrity of sensitive or high-value components.Flexible Production Capabilities

As a flexible production line, it can handle multiple product sizes and specifications without major reconfiguration, allowing manufacturers to respond quickly to market changes.Integration of Advanced Machinery

The line incorporates precision equipment such as line boring machines and portable line boring machines for creating exact holes or alignment features in components.Laser Line Technology

Laser line systems guide cutting, alignment, and inspection processes, enhancing accuracy and reducing errors.

4. Advantages of a Flexible Production Line

Efficiency and Productivity

The belt-supported system ensures continuous, high-speed material transport, minimizing downtime and increasing throughput. Multiple products from the same product line can be processed simultaneously, reducing bottlenecks in production.

Precision and Quality

Using line boring machines and laser line technology, manufacturers achieve high dimensional accuracy. This ensures that every component meets strict tolerances, which is crucial in aerospace, automotive, and high-tech industries.

Adaptability

A flexible production line allows rapid changeovers, enabling manufacturers to produce different products or adapt to new specifications without significant delays. This versatility makes it ideal for companies managing diverse product lines.

Material Safety

Non-destructive cutting prevents structural damage and preserves the integrity of materials, which reduces waste and lowers production costs. This approach is particularly beneficial when working with high-value or delicate components.

Portability and Maintenance

The inclusion of portable line boring machines allows on-site adjustments and maintenance without halting the entire production line. This ensures minimal downtime and continuous operation.

5. Applications of Belt-Supported Non-Destructive Cutting Flexible Production Lines

1. Aerospace Industry

Precision components, such as turbine blades or structural frames, require exact tolerances and non-destructive processing. This line supports high-speed cutting while preserving material integrity.

2. Automotive Industry

Manufacturing of body panels, engine components, and structural parts benefits from flexible, high-accuracy production lines capable of handling different product models on the same line.

3. Electronics and Precision Engineering

High-value components, circuit boards, and sensitive assemblies require non-destructive cutting and precise alignment. Laser-guided flexible production lines ensure quality and reduce defective rates.

4. Machinery and Heavy Equipment

Large-scale components may require line boring machines for precise hole alignment, while belt-supported transport ensures smooth handling. Portable line boring machines allow adjustments for oversized components directly on-site.

6. Integration of Advanced Technology

Line Boring Machines

These machines ensure accurate drilling and alignment of components, critical for assembly and functional performance.

Portable Line Boring Machines

Portable variants bring precision to large or installed components, minimizing the need to disassemble machinery for maintenance.

Laser Line Systems

Laser line technology enhances precision in alignment, cutting, and inspection, reducing errors and improving overall productivity.

7. Why This Production Line is a Game Changer

The Belt-supported Non-Destructive Cutting Flexible Production Line represents a significant advancement in manufacturing technology because it combines:

Speed and efficiency with high precision

Flexibility to handle multiple products or specifications

Non-destructive processing for material safety

Integration of advanced tools like line boring machines, portable line boring machines, and laser line systems

This makes it particularly suitable for companies looking to optimize multiple product lines simultaneously while maintaining quality, reducing waste, and improving responsiveness to market demands.

8. Conclusion

A product line refers not just to a range of related products but to the integrated manufacturing system that produces them efficiently. The Belt-supported Non-Destructive Cutting Flexible Production Line exemplifies how modern manufacturing solutions can enhance productivity, precision, and adaptability. By leveraging advanced machinery such as line boring machines, portable line boring machines, and laser line technologies within a flexible production line, manufacturers can optimize output, maintain high-quality standards, and respond quickly to changing market needs.

In today’s competitive industrial landscape, investing in such a flexible and technologically advanced production line is no longer optional—it is essential for sustaining growth, efficiency, and excellence across multiple product lines.