1. What Is Coil Fed Laser Blanking?

Coil fed laser blanking is a high-efficiency metal cutting process that directly feeds coiled sheet material into a CNC laser cutting machine. Instead of cutting flat metal sheets one by one, the system continuously unrolls the coil, straightens it, and guides it into the Laser blanking line, where a laser precisely cuts the desired blank shapes.

This method eliminates the need for expensive tooling and stamping dies traditionally used in press blanking. By combining laser precision with automated coil feeding, manufacturers can achieve superior flexibility, faster changeovers, and lower overall production costs.

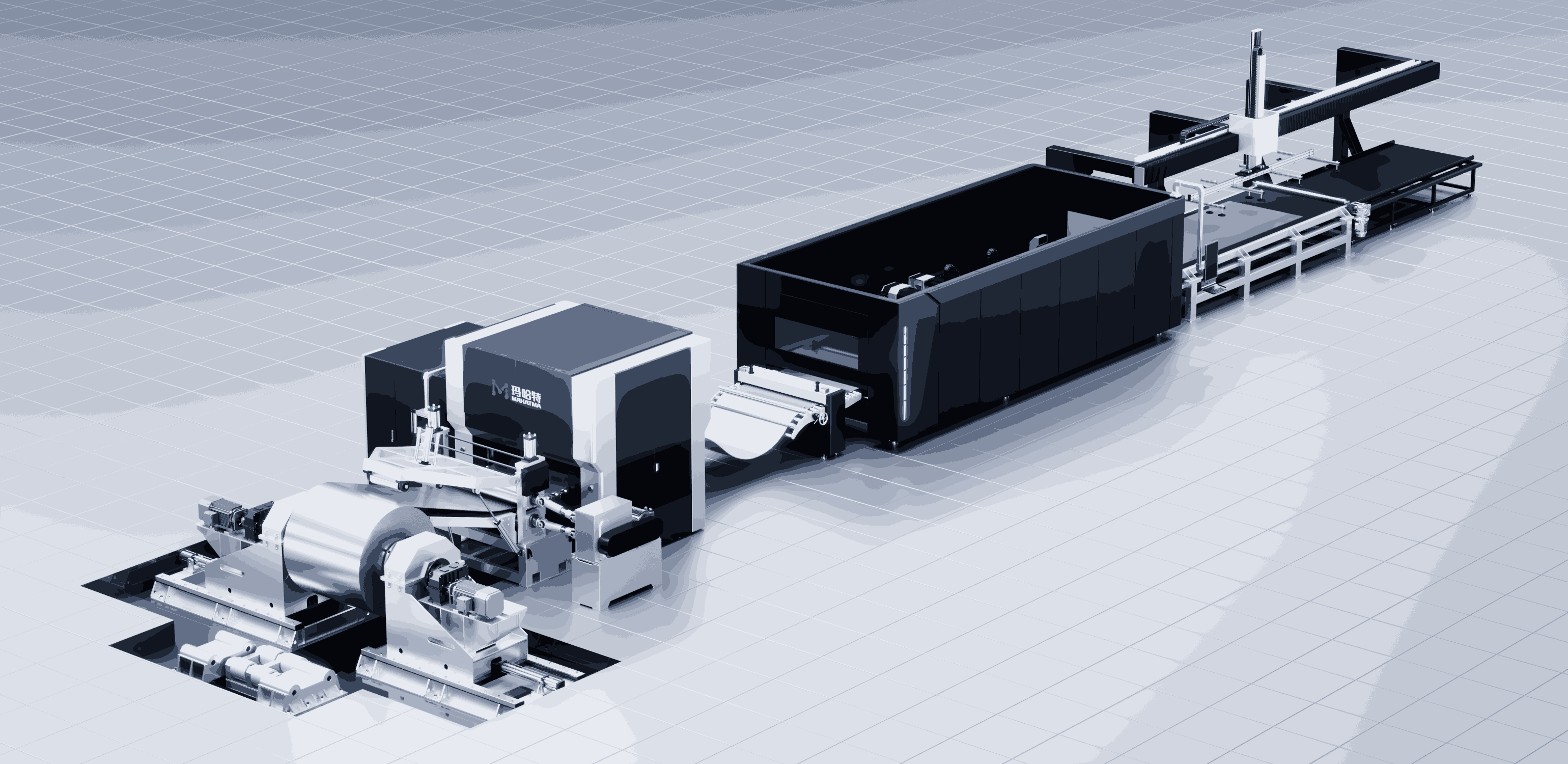

2. Components of a Coil Fed Laser Blanking System

A coil fed laser blanking system typically consists of several key modules that work together in a synchronized process:

Uncoiler: Holds and feeds the metal coil into the line. It ensures smooth unwinding and stable tension control.

Straightener (Leveler): Flattens the coil material to eliminate curvature or tension, preparing it for precise laser cutting.

Feeder: Accurately advances the coil into the cutting area with high-speed servo control.

Coil Laser Cutting Machine: The core of the system, equipped with high-power fiber lasers and CNC controls that perform the blanking (cutting) operation directly from the coil.

Conveyor & Sorting System: Transports cut blanks to stacking or packaging stations automatically.

Stacker / Unloader: Neatly stacks the finished blanks for downstream processes such as forming, welding, or assembly.

Each of these modules integrates seamlessly within the laser blanking line, ensuring consistent throughput and precision during continuous production.

3. How Does Coil Fed Laser Blanking Work?

The process of coil fed laser blanking involves several automated steps that turn a raw coil into precisely cut metal blanks without human intervention:

Step 1: Coil Loading and Uncoiling

A coil of metal — such as steel, aluminum, or stainless steel — is mounted on the uncoiler. The system begins to unwind the coil, maintaining tension to prevent deformation.

Step 2: Straightening and Feeding

The material passes through a straightener, which removes coil set and ensures a flat, even surface. The feeder then delivers the material into the coil laser cutting machine at a controlled rate.

Step 3: Laser Cutting

Using high-power fiber laser beams, the coil laser cutting machine performs non-contact cutting with extreme precision. CNC programming defines the geometry of each blank, enabling easy adjustments for different part designs without the need to change tooling.

Multiple laser heads can operate simultaneously, optimizing cutting speed and material utilization.

Step 4: Part Sorting and Stacking

After cutting, the blanks are automatically separated from scrap material. Robotic arms or conveyors move the finished pieces to a stacking unit, where they are neatly arranged for downstream processing.

Step 5: Scrap Handling and Coil Advancement

The remaining skeleton is rewound or collected for recycling, while the system automatically advances the coil for the next cycle. This continuous flow ensures minimal downtime and maximum output.

4. Advantages of Coil Fed Laser Blanking Systems

The coil fed laser blanking system offers a range of advantages over traditional press blanking and sheet-fed laser cutting.

a. Tooling-Free Flexibility

Unlike mechanical blanking, laser blanking does not require stamping dies. Design changes can be implemented instantly through CNC programming, saving both time and cost during product development.

b. Continuous High-Speed Production

By feeding directly from the coil, the process eliminates manual sheet loading, enabling uninterrupted, automated operation. This makes it ideal for mass production environments.

c. Superior Cutting Precision

The coil laser cutting machine provides smooth, burr-free edges with minimal heat-affected zones. This improves downstream forming performance and reduces post-processing requirements.

d. Reduced Material Waste

The system’s nesting software optimizes the layout of blanks on the coil, minimizing scrap and maximizing material yield.

e. Lower Operational Costs

Without dies or frequent maintenance, operating costs are significantly lower. The reduction in material waste further improves cost efficiency.

f. Enhanced Safety and Cleanliness

The fully enclosed laser blanking line provides a clean, safe environment, minimizing operator exposure to moving parts and debris.

5. Applications of Coil Fed Laser Blanking

The versatility of coil fed laser blanking systems makes them suitable for a wide range of industries:

Automotive Industry: Cutting high-strength steels and aluminum for car body panels, doors, roofs, and structural components.

Home Appliances: Producing enclosures, panels, and internal parts for washing machines, ovens, and refrigerators.

Electronics and Energy: Cutting precision sheet components for enclosures, brackets, and control systems.

Metal Furniture and Construction: Creating customized metal panels with complex designs.

Because of its flexibility and precision, manufacturers in these sectors increasingly rely on coil laser cutting machines to improve efficiency and product quality.

6. Coil Fed Laser Blanking vs. Traditional Press Blanking

| Feature | Coil Fed Laser Blanking | Traditional Press Blanking |

|---|---|---|

| Tooling | No tooling required | Requires expensive dies |

| Setup Time | Fast (digital programming) | Long (die changeover) |

| Flexibility | Easily adapts to design changes | Limited by die geometry |

| Cutting Precision | High – laser-controlled | Moderate – mechanical shearing |

| Material Waste | Low (optimized nesting) | Higher due to fixed die shapes |

| Maintenance | Low | High (die wear and replacement) |

This comparison highlights why laser blanking lines are becoming the preferred choice for manufacturers seeking efficiency and agility.

7. Why Manufacturers Choose Coil Fed Laser Blanking

Leading laser blanking manufacturers design coil-fed systems to meet modern industry needs for just-in-time production and sustainable manufacturing. With the ability to process high-strength materials and perform complex cuts, these systems help companies:

Shorten production cycles

Reduce tooling inventory

Achieve consistent part accuracy

Adapt to new designs instantly

Minimize waste and energy consumption

For OEMs and Tier 1 suppliers in the automotive sector, the coil fed laser blanking system is now a key component of the smart factory concept, integrating digital control, real-time monitoring, and automated workflow.

8. Future Trends in Coil Fed Laser Blanking Technology

The evolution of coil laser cutting machines continues, driven by advancements in automation, AI, and digital manufacturing.

Future developments will include:

AI-based process optimization for automatic nesting and defect detection

IoT connectivity for real-time production monitoring

Hybrid laser and mechanical blanking lines for combined flexibility and speed

Eco-efficient energy use to reduce the carbon footprint

As Industry 4.0 continues to evolve, laser blanking lines will play an even more critical role in high-volume, precision-driven manufacturing environments.

Conclusion

The coil fed laser blanking system represents a breakthrough in modern Sheet Metal processing. By combining continuous coil feeding with advanced coil laser cutting machine technology, manufacturers achieve unmatched flexibility, speed, and precision.

Unlike conventional press blanking, this innovative method eliminates tooling, minimizes waste, and enables on-demand production for industries such as automotive, appliance, and construction.

As a result, laser blanking lines are not just an alternative to traditional blanking—they are the future of smart, sustainable, and highly efficient metal fabrication.