1. What Is a Laser Cutting Machine?

A laser cutting machine is an industrial device that uses a focused laser beam to cut, engrave, or shape materials with high precision. The term “laser” stands for Light Amplification by Stimulated Emission of Radiation. In simple terms, it is a concentrated beam of light energy that generates extreme heat, capable of melting, burning, or vaporizing material at the point of focus.

Laser cutting is widely used across industries because it offers non-contact, high-speed, and high-accuracy processing. Unlike traditional cutting tools, the laser doesn’t wear down, and it provides fine cuts with minimal material deformation.

2. Working Principle of a Laser Cutting Machine

To understand how a laser cutting machine works, it helps to visualize the process step by step:

Step 1: Laser Generation

The laser source (usually a CO₂, fiber, or Nd:YAG laser) produces a concentrated light beam through optical amplification.

Step 2: Beam Focusing

The beam is directed through a series of mirrors or fiber optics to the cutting head. A focusing lens then converges the beam into an extremely fine point—often just a fraction of a millimeter in diameter.

Step 3: Melting or Vaporizing the Material

When the focused beam hits the surface, the energy density is so high that the material either melts, burns, or vaporizes instantly.

Step 4: Material Removal

A jet of assist gas (oxygen, nitrogen, or air) blows away the molten material, leaving a clean, narrow cut line.

Step 5: CNC Control

A CNC laser cutting machine (Computer Numerical Control) automates this entire process. It follows digital design files (CAD/CAM models), moving the laser head along precise paths with micron-level accuracy.

The combination of high-power laser and CNC control creates a system capable of complex geometries, intricate patterns, and repeatable precision.

3. Components of a Laser Cutting System

Every CNC laser cutter consists of several key components working together to ensure accuracy and reliability:

| Component | Function |

|---|---|

| Laser Source | Generates the high-energy laser beam used for cutting. |

| Optical System | Mirrors or fiber optics guide the beam to the cutting head. |

| Focusing Lens | Concentrates the beam into a fine focal point for precision cutting. |

| CNC Controller | Directs motion and cutting paths based on programmed data. |

| Work Table | Supports the material being cut, often with an adjustable height. |

| Assist Gas System | Supplies oxygen, nitrogen, or air to clear molten material and improve edge quality. |

| Cooling System | Regulates temperature to prevent overheating of optics and components. |

| Exhaust System | Removes fumes and particles generated during cutting. |

Each of these components contributes to the overall efficiency and precision of the cutting operation.

4. Types of Laser Cutting Machines

Laser cutters can be categorized based on the type of laser source used:

1. CO₂ Laser Cutting Machine

Uses a gas mixture (carbon dioxide, nitrogen, hydrogen, and helium).

Ideal for cutting non-metal materials like wood, acrylic, and plastics.

Provides smooth, polished cutting edges.

2. Fiber Laser Cutting Machine

Uses optical fiber to amplify the laser beam.

Highly efficient, compact, and powerful—ideal for metals like stainless steel, aluminum, and copper.

Low maintenance and energy-saving design.

Commonly found in CNC laser cutting machines for industrial use.

3. Nd:YAG (Neodymium-Doped Yttrium Aluminum Garnet) Laser

Provides high-intensity beams suitable for metal marking and drilling.

Often used in precision engineering applications.

Each type has unique advantages, but fiber laser cutting machines dominate modern Metal Processing due to their speed, low operational costs, and superior edge quality.

5. How CNC Technology Enhances Laser Cutting

When integrated with CNC (Computer Numerical Control) systems, the laser cutter evolves into a fully automated, intelligent cutting solution.

A CNC laser cutter works by interpreting computer-generated vector files (such as DXF or AI) and translating them into motion commands. The CNC controller guides the cutting head along predefined paths with extraordinary precision—sometimes within ±0.02 mm tolerance.

Advantages of CNC Integration:

High Precision: Automated control ensures consistent quality across batches.

Complex Shapes: Easily cuts intricate patterns, contours, and holes.

Reduced Waste: Optimized cutting paths minimize material loss.

Speed and Efficiency: Rapid motion control shortens production cycles.

Repeatability: Perfect for mass production or custom prototyping.

Thanks to these capabilities, the CNC laser cutting machine has become a cornerstone of modern fabrication workshops and automated manufacturing plants.

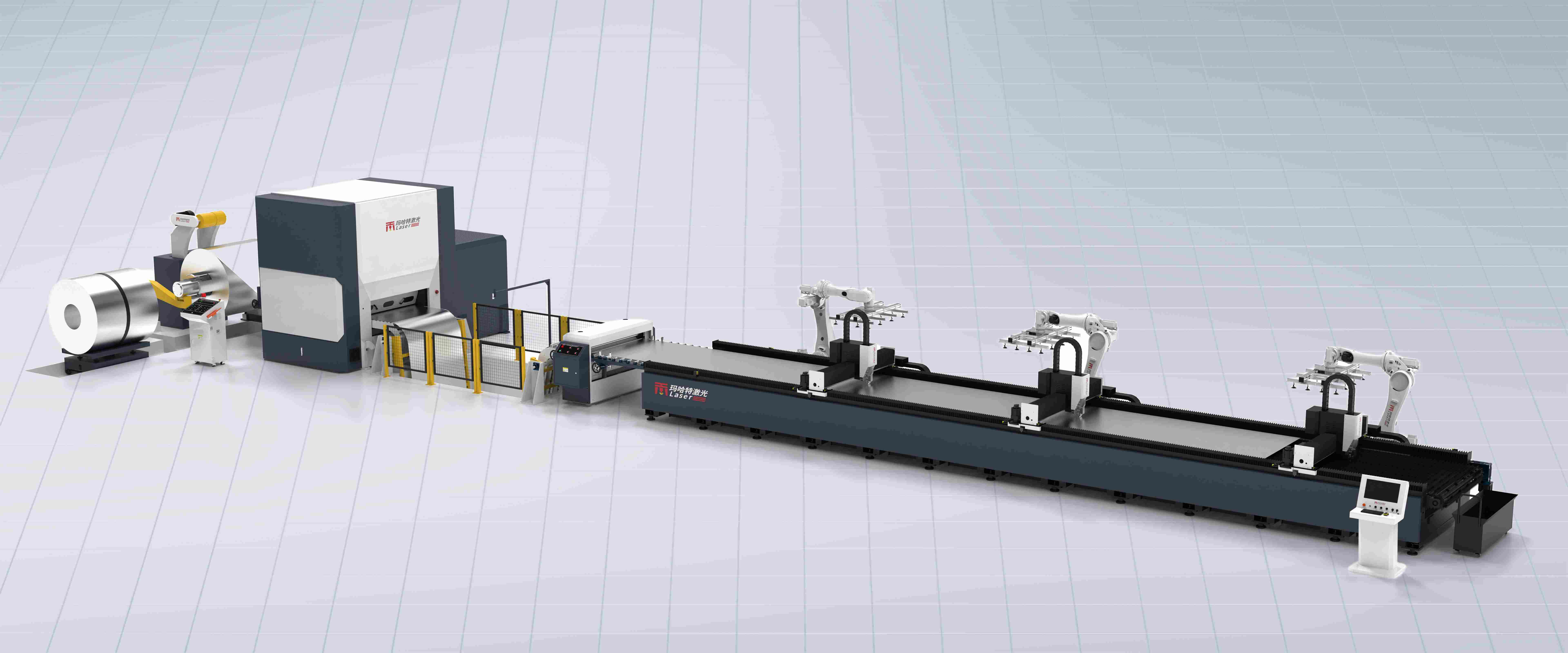

6. Laser blanking line: The Future of Metal Sheet Processing

In the Sheet Metal industry, laser blanking represents a revolutionary leap forward. A Laser Blanking Line is an advanced production system that replaces traditional stamping with laser-based blank cutting.

Instead of using costly and time-consuming mechanical dies, the laser blanking process employs powerful CNC laser cutting machines to cut shapes directly from coil-fed metal sheets.

How It Works:

Metal coils are fed automatically into the line.

Flattened sheets move under a CNC laser cutter.

The laser beam cuts parts directly according to digital designs.

The finished blanks are separated and stacked automatically.

This system provides flexibility, speed, and cost savings by eliminating tooling requirements.

7. Advantages of Laser Blanking Lines

As leading Laser Blanking Manufacturers develop this technology, several key benefits have emerged:

Tool-Free Production: No physical dies are required, reducing setup time and cost.

Flexible Design Change: Digital files can be updated instantly for new models.

High Accuracy: Lasers produce clean, burr-free edges with tight tolerances.

Material Optimization: Software nesting minimizes scrap material.

Automated Workflow: Integrated with robotics and conveyors for continuous production.

Ideal for EV and Automotive Industries: Perfect for cutting lightweight metal sheets and high-strength steel used in electric vehicles.

The Laser Blanking Line represents the evolution of traditional blanking systems, providing manufacturers with unmatched flexibility and productivity.

8. Applications of CNC Laser Cutting Machines

Laser cutting is used across multiple industries, including:

1. Automotive

Cutting body panels, chassis parts, and interior components. Laser blanking lines are increasingly used for mass-producing sheet metal blanks.

2. Aerospace

High-precision cutting of turbine components, engine parts, and structural elements from aluminum and titanium alloys.

3. Electronics

Used for precise cutting of enclosures, connectors, and PCB boards.

4. Construction and Architecture

Laser cutting enables decorative panels, façade elements, and intricate metal designs.

5. Energy Sector

Applied in manufacturing solar panels, battery components, and fuel cell structures.

6. Custom Manufacturing

Ideal for small-batch, prototype, or customized part production thanks to digital control flexibility.

9. Advantages of Using CNC Laser Cutters

The CNC laser cutter provides significant advantages over mechanical cutting methods:

Exceptional Precision – Laser spot diameter can be as small as 0.1 mm.

Smooth Cutting Edge – No burrs or need for secondary finishing.

Minimal Thermal Distortion – Focused heat minimizes deformation of materials.

Wide Material Compatibility – Works with metals, plastics, ceramics, and composites.

Reduced Maintenance – Fewer moving parts compared to mechanical cutters.

Automation-Ready – Easily integrated into robotic lines and smart factories.

These features make CNC laser cutting machines the preferred solution for both small workshops and high-volume production lines.

10. Challenges and Considerations

While laser cutting offers numerous benefits, it also presents challenges:

High Initial Investment: Advanced laser systems and CNC controls require significant capital.

Reflective Materials: Metals like copper and brass can reflect laser energy, requiring special setups.

Maintenance: Optics and lenses must remain clean and precisely aligned.

Power Consumption: High-power lasers can increase energy use, though fiber lasers mitigate this issue.

Nevertheless, the long-term gains in productivity and quality often outweigh these challenges.

11. The Role of Laser Blanking Manufacturers

Laser Blanking Manufacturers play a critical role in advancing industrial efficiency. They design, build, and integrate Laser Blanking Lines equipped with high-speed CNC laser cutters to replace conventional stamping presses.

These manufacturers focus on:

Enhancing laser speed and cutting quality

Integrating AI and digital twin technology for production monitoring

Developing eco-friendly systems with reduced material waste

Offering modular, scalable solutions for diverse industries

Through innovation and engineering excellence, Laser Blanking Manufacturers are transforming how sheet metal fabrication is performed worldwide.

12. The Future of Laser Cutting Technology

The future of CNC laser cutting machines and Laser Blanking Lines will continue to evolve through:

AI and Automation: Smart sensors for real-time quality monitoring.

Hybrid Systems: Combining laser cutting with bending and welding.

Energy Efficiency: Next-gen fiber lasers with higher power conversion rates.

Industry 4.0 Integration: Full digital connectivity for remote operation and predictive maintenance.

As industries pursue lightweight materials and flexible manufacturing, laser-based systems will remain at the core of intelligent production.

Conclusion

Understanding how a laser cutting machine works reveals why it has become one of the most transformative technologies in modern manufacturing.

By focusing a high-energy laser beam to melt or vaporize materials under precise CNC control, the CNC laser cutting machine and CNC laser cutter deliver unmatched precision, speed, and design flexibility.

Furthermore, the emergence of the Laser Blanking Line—developed and refined by leading Laser Blanking Manufacturers—is reshaping the future of sheet metal production, providing tool-free, automated, and efficient solutions for industries worldwide.

As manufacturing continues to embrace digitalization, automation, and sustainability, laser cutting technology stands as a shining example of how innovation and precision can revolutionize the way we build the world.