Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China

If you have more questions to ask us and get best quote, please contact us now directly via

This serie of machines adopts servo motors, CNC technology and a self-developed intelligent super-leveling CNC system. There are a large number of levleing process parameters in the system, which can automatically set the leveling pressure and initial work according to different coils and sheets with parameters, and can modify, store, call process and edit equipment parameters at any time.

Equipped with inteilligent functions such as automatic laser three-dimensional detection, misoperation identification and early warning, it is a high-end leveling equipment integrating cutting-edge technology. Servo motors provide the capability for high speed, high torque and precise position control, helping to achieve fast, smooth leveling operations. Reducing hydraulic oil usage and energy consumption makes servo-hydraulic levelers more environmentally friendly.

The Servo CNC Leveling Machine is equipped with a Siemens PLC controller and utilizes a Siemens frequency converter for optimized operating speed. Centralized control is facilitated through a user-friendly touchscreen interface, ensuring an intuitive experience. For safety, emergency switches are positioned at key points near the machine’s inlet and outlet, allowing for quick access during operation. A digital display provides real-time information on displacement, enabling rapid and precise leveling of complex hardware components that typically require prolonged manual efforts.

Automatic Roller Extraction: The roller can be fully automated for easy cleaning.

Automated Quantity Calculation: Seamlessly integrates with various MRP and ERP systems for effective monitoring of equipment startup, operational time, and automatic part counting.

Robust Structural Support: The design features full support of the roller, enhancing structural integrity.

Real-Time Monitoring: The machine is equipped with an automatic monitoring function for ongoing equipment and production status checks, facilitating maintenance and repairs.

Enhanced Operating Rigidity: A wide support shaft improves operational stability and minimizes indentation across a broader range.

Remote Control Capability: For users in remote locations, our engineers can assist with machine adjustments and troubleshooting.

Optoelectronic Safety Features: Designed to prevent accidents caused by unauthorized personnel or workpieces entering the machine.

Premium Finish: The machine is coated with high-quality BMW baking paint, providing a durable and luxurious appearance.

Automatic Flatness Detection: Optional feature for precision scanning and accuracy detection.

Fully Automatic Adjustment: Optional unmanned operation for streamlined processes.

Intelligent Operating System: Enhanced dynamic performance and stability with smooth software operation; features an integrated fast leveling mode.

MHTW Series High-Precision Leveling: Boasts independent intellectual property rights and patented technologies, delivering ultra-efficient leveling with intelligent control.

Self-Lubricating System: High-tech, maintenance-free system that allows for one-click low oil pressure alarms, preventing machine wear from delayed lubrication.

Remote Cloud Control: Enables remote monitoring of equipment status, fault diagnosis, and real-time cloud-based oversight.

Innovatively Developed Gearbox: Features a gear universal joint transmission for improved acceleration, speed, and impact resistance.

Hollow Structure Design: The machine tool’s construction minimizes heating areas, ensuring long-term stability and preventing thermal deformation, which maintains leveling accuracy over time.

This state-of-the-art Servo CNC Leveling Machine is designed for efficiency, reliability, and user-friendly operation, making it an invaluable asset in any production environment.

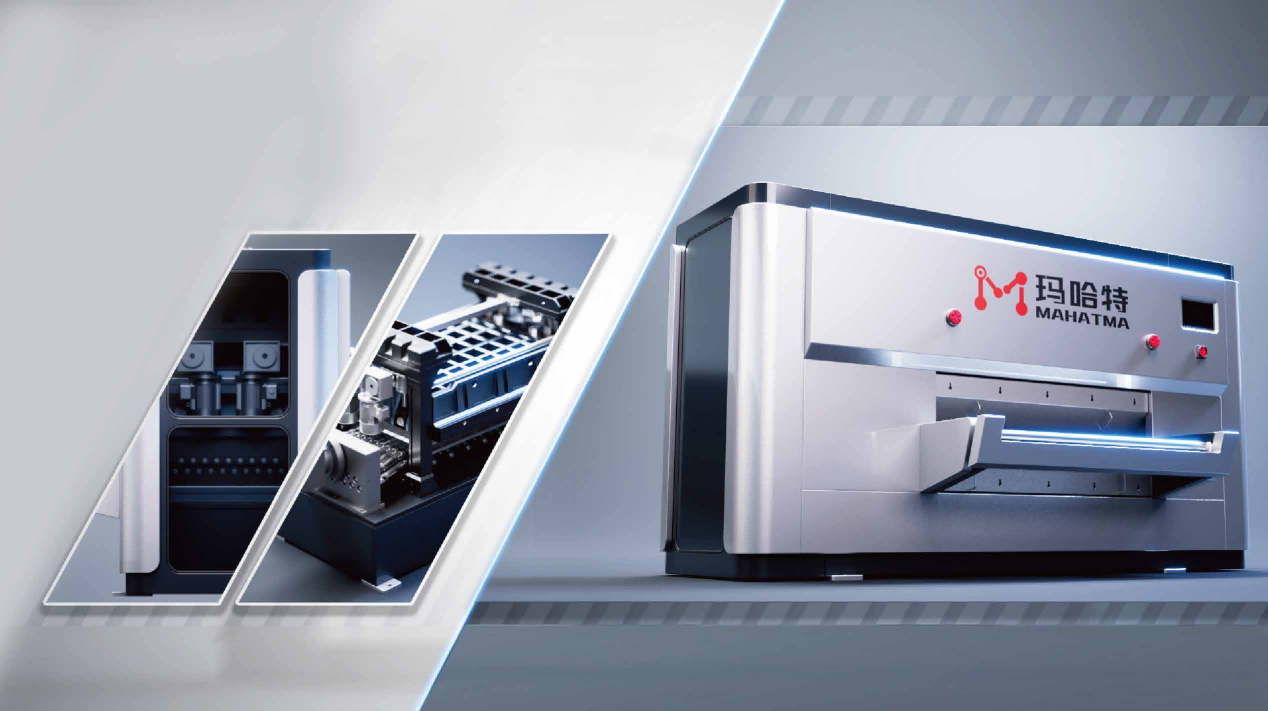

Noble and Luxurious

Industrial aesthetic design, extraordinary master BMW paint, multi-layer precision painting process, symbol of strength, highlighting noble temperament and quality;

Kunpeng Structure

Patented structural technology, high-strength structure, shock-proof and pressure-resistant, rock-solid, fully open design, one-click spread;

Metrical Roller Set

Servo electromechanical leveling gap control, precise and efficient, using the latest energy-saving technology, energy-saving and environmentally friendly, great power;

Energy Saving Pioneer

Dense full support structure combined with wide support shaft, high strength and less indentation, enhanced load-bearing capacity, long-lasing stability, and elimination of deformation;

Benchmark Performance

Smart roller box pull-out cleaning system for quick and easy cleaning of leveling and support rollers! No.1 in China;

Smart Technology

Intelligent human-machine interface, real-time monitoring and adjustment, remote control, automatic counting and other cutting-edge functions;

Security Guard

Overload protection, photoelectric protection, intelligent early warning of misoperation, etc;

Full Scene

Can be seamlessly connected with various production lines to improve the automation of the production line;

Anti-Collapse Function

Dynamic servo compensation technology is used to prevent angle collapse and improve leveling accuracy and material surface quality.

| Model | MHTW60-400-19 | MHTW60-600-19 | MHTW60-800-19 | MHTW60-1300-19 | MHTW60-1600-19 |

| Width | 0-400mm | 0-600mm | 0-800mm | 0-1300mm | 0-1600mm |

Roll diameter | 60 | 60 | 60 | 60 | 60 |

| Rated thickness | 1.0-6.0mm | 1.0-6.0mm | 1.0-6.0mm | 1.0-6.0mm | 1.0-6.0mm |

| Maximum thickness | 12.0mm | 12.0mm | 12.0mm | 12.0mm | 12.0mm |

| Number of rolls | 19 | 19 | 19 | 19 | 19 |

| Shortest part | 100 | 100 | 100 | 100 | 100 |

| Leveling speed | 0-10m/min | 0-10m/min | 0-10m/min | 0-10m/min | 0-10m/min |

| Voltage | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V | AC three-phase 380V AC3-phase 380V |

| Optional | 1.Loading and unloading and reclaiming manipulators2. Loading and unloading joint robots 3.Automatic detection platform 4. inlet and outflow assembly line 5. Automatic stacking lifting platform 6. Roller quick cleaning device | ||||

We provide not only equipment but also professional services throughout the entire lifecycle:

Simply fill out the form below as best you can. And don't sweat the details

Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China