Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China

If you have more questions to ask us and get best quote, please contact us now directly via

NO roller imprint exists, meet high precision

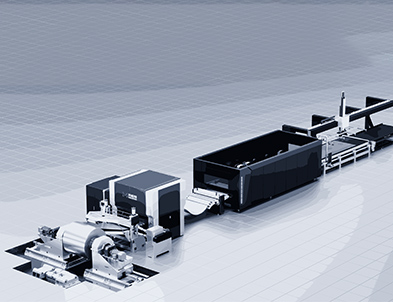

Production Line Series and Application Scope

| Series Nam | Thickness Range | Examples of Applied Industries | Common Materials |

| UL Ultra-Thin Plate Series | 0.1–0.8 mm | Precision Electronics, Photovoltaic Backsheets, Small Home Appliances | Cold-Rolled Steel, Stainless Steel, Aluminum |

| TL Thin Plate Series | 0.3–3.0 mm | Automotive Sheet Metal, Home Appliance Casings, Kitchen and Bathroom Hardware | Galvanized Sheets, Carbon Steel, Aluminum Alloys |

| ML Medium - Heavy Plate Series | 1.0–8.0 mm | Construction Machinery, Electrical Cabinets, Rail Transit Equipment | Hot-Rolled Steel, Stainless Steel |

| HL Heavy Plate Series | 3.0–20.0 mm | Structural Steel Components, Heavy Machinery, Marine Plates | High-Manganese Steel, Aluminum-Magnesium Alloys |

| XL Extra-Heavy Plate Series | 6.0–25.0 mm | Building Steel Structures, Heavy-Duty Manufacturing, Energy Equipment | Steel Plates, Titanium Alloys |

Comparison of Core Parameters Across Series

| Parameter Category | UL Ultra-Thin Plate Series | TL Thin Plate Series | ML Medium - Heavy Plate Series | HL Heavy Plate Series | XL Extra-Heavy Plate Series |

| Thickness Range | 0.1–0.8mm | 0.3–3.0mm | 1.0–8.0mm | 3.0–20mm | 6.0–25mm |

| Width Range | 200–1500mm | 600–2500mm | 600–2500mm | 600–2500mm | 600–2500mm |

| Positioning Accuracy | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m | ±0.02mm/m |

| Laser Power | Standard Con[guration | Standard Con[guration | Standard Con[guration | Standard Con[guration | Standard Con[guration |

| Blanking Method | Standard Con[guration | Standard Con[guration | Standard Con[guration | Standard Con[guration | Standard Con[guration |

Industry Selection Guide

| Industry | IndustRecommended Series | Common Materials | Recommended Width | RecommendedLaser Power |

| Automotive Manufacturing | TL / ML / HL | High-Strength Steel, Aluminum Alloy, Stainless Steel | 1300–1600 mm | 3–12 kW |

| Home Appliance Industry | UL / TL | Cold-Rolled Steel, Galvanized Sheet, Color-Coated Sheet | 1000–1300 mm | 3–6 kW |

| Rail Transit | ML / HL | Stainless Steel, Aluminum Plate, Hot-Rolled Steel | 1600–2100 mm | 6–12 kW |

| Building Steel Structure | HL / XL | Carbon Steel, Alloy Steel, Thick Plate | 1600–2100 mm | 12–20 kW |

| Sheet Metal Processing (MultipleIndustries) | TL / ML | Various Types of Plates (Small Batch, Multiple Varieties) | 1000–1600 mm | 3–12 kW |

| New Energy / Photovoltaics | UL / TL | Thin Aluminum, Galvanized Sheet, Silicon Steel Sheet | 1000–1300 mm | 3–6 kW |

| Shipbuilding and Heavy Industry | XL | Thick Steel Plate, Special Alloy | 1600–2100 mm | 12–20 kW |

We provide not only equipment but also professional services throughout the entire lifecycle:

Production demand analysis, layout optimization, and return on investment assessment.

Professional teams ensure rapid equipment startup.

Multi-level training in system operation, program-ming, and maintenance.

24/7 equipment status monitoring and fault early warning.

Nationwide service network with 4-hour technical response.

Continuous technology updates to maintain equipment competitiveness.

Simply fill out the form below as best you can. And don't sweat the details

Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China