Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China

If you have more questions to ask us and get best quote, please contact us now directly via

Meet high precision

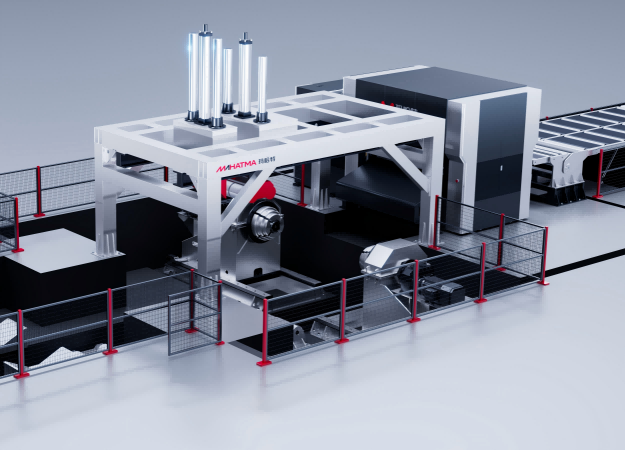

Production Line Series and Application Scope

| Series Name | Thickness Range | Examples of Applied Industries | Common Materials |

| US Ultra-Thin Plate Series | 0.2–1.0 mm | Lithium battery copper foil electrode slitting,Flexible OLED substrate,EM shielding film cutting,Superconducting cooling tape,Food packaging aluminum foil,Photovoltaic backsheet PET film | Copper foil,Aluminum film,Polyimide,Composite materials,Polymer films |

| TS Thin Plate Series | 0.3–3.0 mm | New energy vehicle battery trays, Smartwatch metal midframes, Elevator mirror decorative panels, Medical CT machine housings, Drone airframes, Smart home control panels, Rail transit interior trim panels, Precision instrument enclosures, Industrial robot protective shields | Aluminum alloy , Stainless steel , Galvanized steel sheet , Color coated steel sheet , Anodized aluminum |

| MS Medium - Heavy Plate Series | 0.5–8.0 mm | High-speed rail car side panels,Data center server racks ,Cold chain logistics containers,Agricultural harvester blades,Multi-level parking garage frameworks,Commercial kitchen equipment,Environmental dust collector housings,Ship bulkhead panels,Wind turbine control cabinets | Weathering steel,High-strength steel,Stainless steel,Sandwich panel,Anti-corrosion coated steel |

| HS Heavy Plate Series | 3.0–12.0 mm | Oil pipeline flanges,Excavator track plates,Bridge steel structures,Heavy-duty truck frames,Pressure vessel heads,Mining crusher teeth plates,Injection molding machine templates,Marine propeller components,Hydraulic press columns | Wear-resistant steel,High-strength steel,Titanium alloy,Hot-rolled plate,Alloy cast steel,Quenched steel |

| XS Extra-Heavy Plate Series | 4.0–16.0 mm | Aircraft carrier flight decks,Rocket launch pads,Nuclear reactor pressure vessels,Deep-sea drilling platforms,10,000-ton hydraulic press bases,Hydroelectric turbine casings,Spacecraft support rings,Particle accelerator chambers,Seismic-resistant structures for super-tall buildings | Armor steel,High-nickel alloy,Stainless steel clad plate,Special alloy,Metal matrix composite |

Comparison of Core Parameters Across Series

| Parameter Category | US Ultra-Thin Plate Series | TS Thin Plate Series | MS Medium - Heavy Plate Series | HS Heavy Plate Series | XS Extra-Heavy Plate Series |

| Thickness Range | 0.2–1.0mm | 0.3–3.0mm | 0.5–8.0mm | 3.0–12.0mm | 6.0–25.0mm |

| Width Range | 400–1300mm | 600–2600mm | 600–2600mm | 600–2600mm | 600–2600mm |

| Line Speed | 0-200m/min optional | 0-200m/min optional | 0-60m/min optional | 0-40m/min optional | 0-40m/min optional |

| Leveling Accuracy | 0.1-0.5mm 0.5-1.0mm Above 1.0mm | 0.1-0.5mm 0.5-1.0mm Above 1.0mm | 0.1-0.5mm 0.5-1.0mm Above 1.0mm | 0.1-0.5mm 0.5-1.0mm Above 1.0mm | 0.1-0.5mm 0.5-1.0mm Above 1.0mm |

| Roll weight | 0.5 to 5T optional | 5 to 20T optional | 10 to 30T optional | 10 to 30T optional | 10 to 30T optional |

| Slitting Accuracy | ±0.05mm | ±0.05mm | ±0.05-0.08mm | ±0.05-0.1mm | ±0.05-0.1mm |

| Leveling Machine | Manual/CNC/Hydraulic | Manual/CNC/Hydraulic | Manual/CNC/Hydraulic | CNC/Hydraulic | CNC/Hydraulic |

Some parameters are for reference only. Final specifications are subject to customization.

We provide not only equipment but also professional services throughout the entire lifecycle:

Production demand analysis, layout optimization, and return on investment assessment.

Professional teams ensure rapid equipment startup.

Multi-level training in system operation, program-ming, and maintenance.

24/7 equipment status monitoring and fault early warning.

Nationwide service network with 4-hour technical response.

Continuous technology updates to maintain equipment competitiveness.

Simply fill out the form below as best you can. And don't sweat the details

Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China