Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China

If you have more questions to ask us and get best quote, please contact us now directly via

Full-Process Traceability

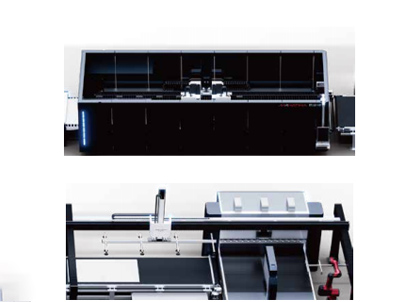

The Kaiping Laser Bending Flexible Production Line is a fully integrated sheet metal processing solution, combining unwinding and leveling, laser cutting, bending units, and intelligent palletizing. Designed for unmanned production from coiled material to finished bent or welded parts, it dramatically enhances production efficiency while reducing labor costs. The system supports full-process traceability, with one item, one code, and automatic labeling for precise tracking throughout production.

Featuring dual- or multi-head laser technology, seamless MES/ERP integration, and intelligent automated sorting, the line enables a complete smart manufacturing loop: monitoring, analysis, decision-making, execution, and traceability. Its flexible design allows rapid changeovers for multiple varieties and small-batch production, eliminating mold costs and maximizing investment returns. Widely applied in automotive, medical devices, home appliances, aerospace, and 5G communications, this system reshapes the sheet metal production process, delivering unparalleled speed, flexibility, quality, and cost control.

We provide not only equipment but also professional services throughout the entire lifecycle:

Production demand analysis, layout optimization, and return on investment assessment.

Professional teams ensure rapid equipment startup.

Multi-level training in system operation, program-ming, and maintenance.

24/7 equipment status monitoring and fault early warning.

Nationwide service network with 4-hour technical response.

Continuous technology updates to maintain equipment competitiveness.

Simply fill out the form below as best you can. And don't sweat the details

Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China