Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China

If you have more questions to ask us and get best quote, please contact us now directly via

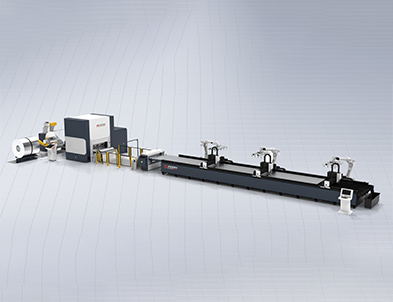

Multi-head laser cutting

| Parameter | Specification / Options |

| Acceleration | 1.5g |

| Maximum Material Weight | 5t–20t (optional) |

| Positioning Accuracy | ±0.02mm/m |

| Leveling Accuracy | 0.1–0.5mm/m |

| Laser Cutting Area | 6015 / 6020 / 8020 / 12020 |

| Bed Platform | Integrated rolling, zoned dust removal, bottom sealing |

| Maximum Material Width | 2800mm |

| Leveling Machine Type | CNC type / Wave pressure type |

| Maximum Material Thickness | 10.0mm |

| Maximum Feeding Speed | 35 m/min |

| Laser Power | 2000W–20000W (optional) |

| Optional Equipment | Laminating machine, sheet peeling suction cup, robot, waste material collection rack, automatic stacking machine |

We provide not only equipment but also professional services throughout the entire lifecycle:

Production demand analysis, layout optimization, and return on investment assessment.

Professional teams ensure rapid equipment startup.

Multi-level training in system operation, program-ming, and maintenance.

24/7 equipment status monitoring and fault early warning.

Nationwide service network with 4-hour technical response.

Continuous technology updates to maintain equipment competitiveness.

Simply fill out the form below as best you can. And don't sweat the details

Phone: +86 135 2793 7257

Email:support@gdmht.com

Address: MAHATMA Industrial Park, Jiaying 1st Street, Southwest Shijie, Dongguan City, Guangdong Province, China